Jali For Plastic Recycling Industries

Durable Jali for Plastic Recycling: Precision Solutions for Efficient Filtration Processes

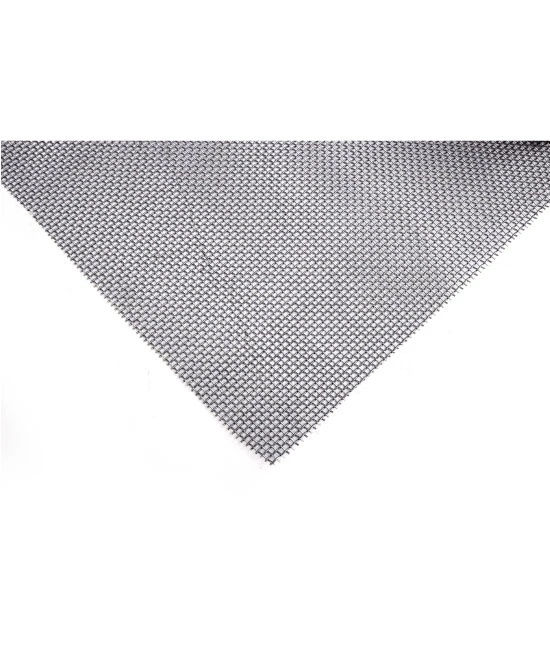

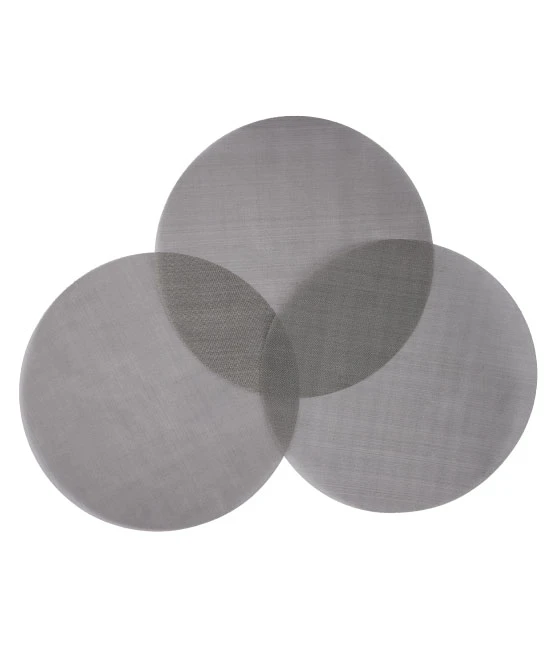

India International Co. offers high-quality jali (screen) for plastic recycling, designed to enhance the efficiency and effectiveness of the recycling process. Our jalis are crafted with precision to meet the stringent requirements of plastic recycling, ensuring optimal performance and durability.

Key Features:

❖ High Filtration Efficiency: Our jalis are engineered to provide excellent filtration, effectively removing contaminants and impurities from

recycled plastic materials.

❖ Durable Construction: Made from premium-grade materials such as stainless steel, our jalis are built to withstand the harsh conditions of

plastic recycling processes, including high temperatures and pressures.

❖ Corrosion Resistance: Designed to resist corrosion and wear, our jalis ensure long-lasting performance even in demanding recycling environment.

❖ Customizable: Available in various sizes, mesh specifications, and configurations to meet the specific needs of different plastic recycling

applications.

❖ Precision Weaving: Manufactured using advanced weaving techniques to ensure uniform mesh openings and consistent filtration performance.

Jali For Plastic Recycling Industries

Durable Jali for Plastic Recycling: Precision Solutions for Efficient Filtration Processes

India International Co. offers high-quality jali (screen) for plastic recycling, designed to enhance the efficiency and effectiveness of the recycling process. Our jalis are crafted with precision to meet the stringent requirements of plastic recycling, ensuring optimal performance and durability.

Key Features:

❖ High Filtration Efficiency: Our jalis are engineered to provide excellent filtration, effectively removing contaminants and impurities from

recycled plastic materials.

❖ Durable Construction: Made from premium-grade materials such as stainless steel, our jalis are built to withstand the harsh conditions of

plastic recycling processes, including high temperatures and pressures.

❖ Corrosion Resistance: Designed to resist corrosion and wear, our jalis ensure long-lasting performance even in demanding recycling environment.

❖ Customizable: Available in various sizes, mesh specifications, and configurations to meet the specific needs of different plastic recycling

applications.

❖ Precision Weaving: Manufactured using advanced weaving techniques to ensure uniform mesh openings and consistent filtration performance.

Product Specification

ADVANTAGES

Cost-Effective:

Durable and reliable jalis reduce the need for frequent replacements, minimizing downtime and maintenance costs.

Versatility:

Suitable for various plastic recycling applications, providing flexible and reliable filtration solutions.

Custom Solutions:

We offer customized jalis to meet the specific requirements of different recycling processes and equipment.

Enhanced Product Quality:

High-efficiency filtration ensures the removal of contaminants, resulting in superior quality recycled plastic.

Durability:

Constructed from high-quality materials to withstand the rigors of plastic recycling, offering long-term reliability and performance.

APPLICATION

Plastic Recycling Plants:

Used in recycling facilities to filter out contaminants from shredded or melted plastic, ensuring high-quality recycled materials.

Extrusion Processes:

Essential in extrusion processes to maintain the purity of recycled plastic by removing impurities before the plastic is formed into new products.

Injection Molding:

Applied in injection molding to ensure the quality and consistency of recycled plastic feedstock.

Blow Molding:

Used in blow molding processes to filter recycled plastic, preventing defects and ensuring the integrity of the final products.

Pelletizing:

Utilized in the pelletizing process to filter molten plastic and produce high-quality plastic pellets.